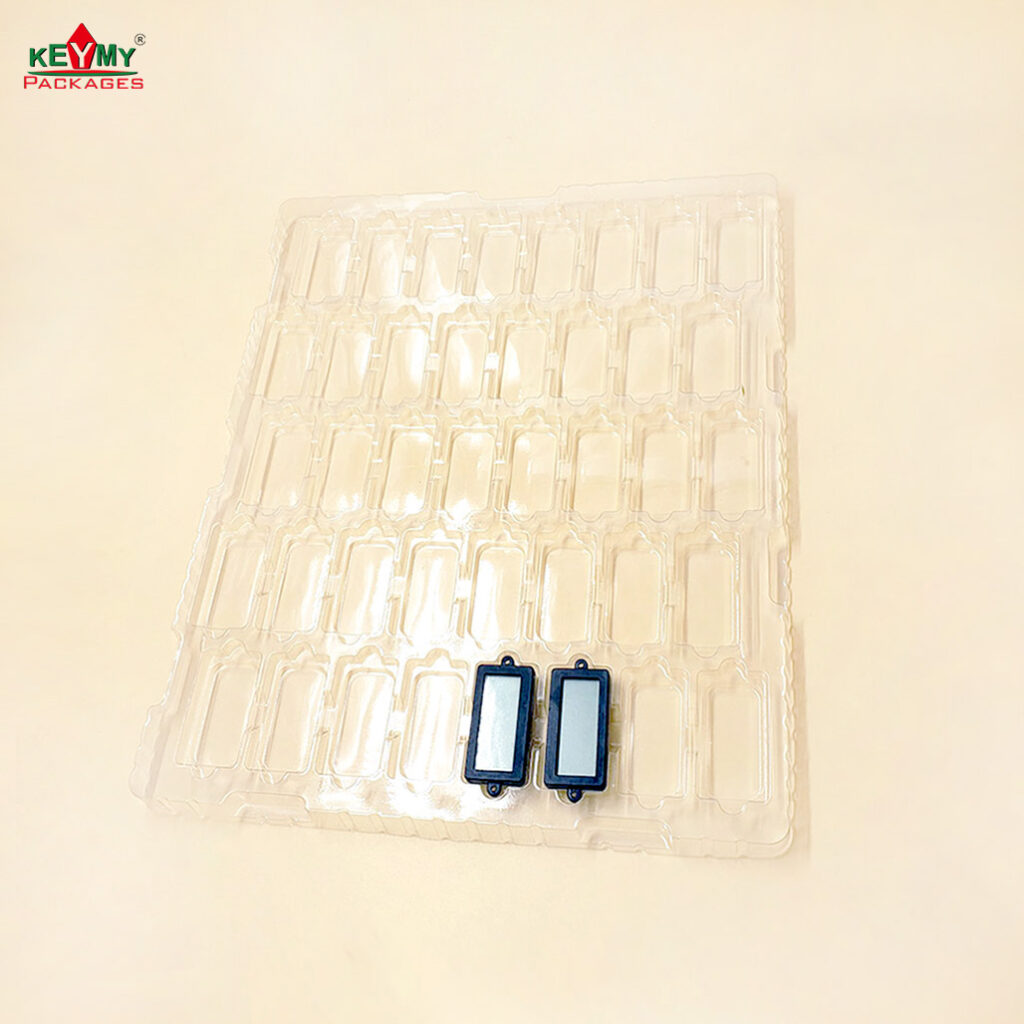

Vacuum plastic packaging, also known as containerless packaging, can save a lot of packaging raw materials, reduce packaging waste, and meet the requirements of moderate and reduced packaging advocated globally. Vacuum plastic packaging is a new packaging technology and material developed in the 1980s. This new technology and material have been used for packaging solid small items such as tablets, pills, health pills, and sugar cubes. With the gradual rise of the plastic packaging industry, the application of vacuum plastic packaging has become more widespread. In recent years, vacuum plastic packaging has been used in China for the packaging of small appliances, handicrafts, toys, shoes, and some electronic products, as well as the turnover of electronic anti-static trays in electronic factories, and the production of anti-static trays on automated assembly lines. The turnover of finished packaging, hardware stamping parts, car parts, computer connectors, electronic components, and other materials such as MP3 players, headphones, USB, toys, batteries, handicrafts, and duckbill caps is equipped with anti-static vacuum plastic turnover trays.

Advantages of vacuum packaging

The main advantages of vacuum plastic packaging are saving raw materials, light weight, convenient transportation, good sealing performance, and meeting the requirements of environmentally friendly and green packaging; Can package any irregular products without the need for additional cushioning materials for packaging; The packaged products are transparent and visible, have a beautiful appearance, are easy to sell, and are suitable for mechanized and automated packaging, facilitating modern management, saving manpower, and improving efficiency.

Vacuum blister packaging is carried out on specialized packaging machinery. In recent years, with the development of commodity packaging towards mechanization and automation, manufacturers of thermoforming packaging machinery have developed rapidly. There are already multiple professional manufacturers of vacuum blister packaging equipment at home and abroad. Although the structural forms of vacuum forming packaging machines are different, their principles are basically similar. The working principle of vacuum plastic packaging is that after the vacuum plastic sheet is heated in the vacuum machine oven, due to the principle of thermal expansion and contraction, the sheet begins to become soft and larger. Then it is vacuum formed on a specific copper or aluminum mold. Stamping and cutting the formed blister according to different product requirements.

Usage effect

The use of packaging can increase the beauty, value, grade, and promote sales of goods. The main purpose of using packaging is to increase the sales of goods. Of course, only good packaging can achieve these perfect effects. To achieve some perfect effects, a complete packaging design process is required. The concept of packaging design is mainly based on the consumer’s ideas and selection methods. If the packaging is designed well, it can also save costs for the packaging of goods.

Advantages of use Vacuum products started around the 1980s and 1990s, with the initial packaging only for loading items. Later, due to changes in people’s consumption choices, most consumers used different packaging to enhance the diversity of items in order to better meet their own ideas and various appearance requirements. Plastic vacuum packaging has a unique appearance, is lightweight, durable, recyclable, and has a lower price. Of course, it is only feasible to choose the packaging that is suitable for one’s own items.