Four color printing (CMYK) 1 Four color “refers to the use of four types of ink: cyan (C), magenta (M), yellow (Y), and black (K). By mixing these four inks, all colors can be produced, ultimately resulting in full-color images and text.

- This is the most basic and common printing method, and different results will be obtained depending on the substrate used.

Spot color printing or Pantone color printing 1 Spot color printing uses specific custom mixed inks to print specific colors, resulting in brighter tones than four-color blends. Common spot colors include metallic colors such as gold and silver. - Spot color printing comes in a wide variety of colors, please refer to the Pantone Color Guide. Spot color printing cannot produce gradients. If necessary, add four-color printing.

UV coating 1. UV coating enhances the effect of specific areas of printed materials by applying a glossy effect, making certain patterns or text appear more three-dimensional.

- This technology is usually used in combination with matte lamination; When used together with glossy lamination, it will not produce any effect.

Hot stamping 1. Hot stamping uses heat and pressure to transfer metal foil to the substrate, producing a special metallic luster on the surface. - Common colors for hot stamping include gold, silver, red, green, and blue. But hot stamping is limited to one color, and not all colors can be purchased in the market.

Embossing 1. Embossing uses a pair of male and female molds to press the substrate, forming a raised (relief) or recessed (depression) pattern, giving it a tactile and three-dimensional effect. - This technology can be used for paper of various thicknesses, but is not suitable for cardboard.

Inkjet coding 1 Inkjet coding involves using inkjet printers to directly apply markings such as production date, expiration date, batch number, and company logo to products. - It can print simple characters and patterns more flexibly.

Composite bag 1 Composite bags are suitable for vacuum or regular packaging of products such as food, electronics, chemicals, pharmaceuticals, and tea. - They can undergo processes similar to paper, such as screen printing, conventional printing, and hot stamping.

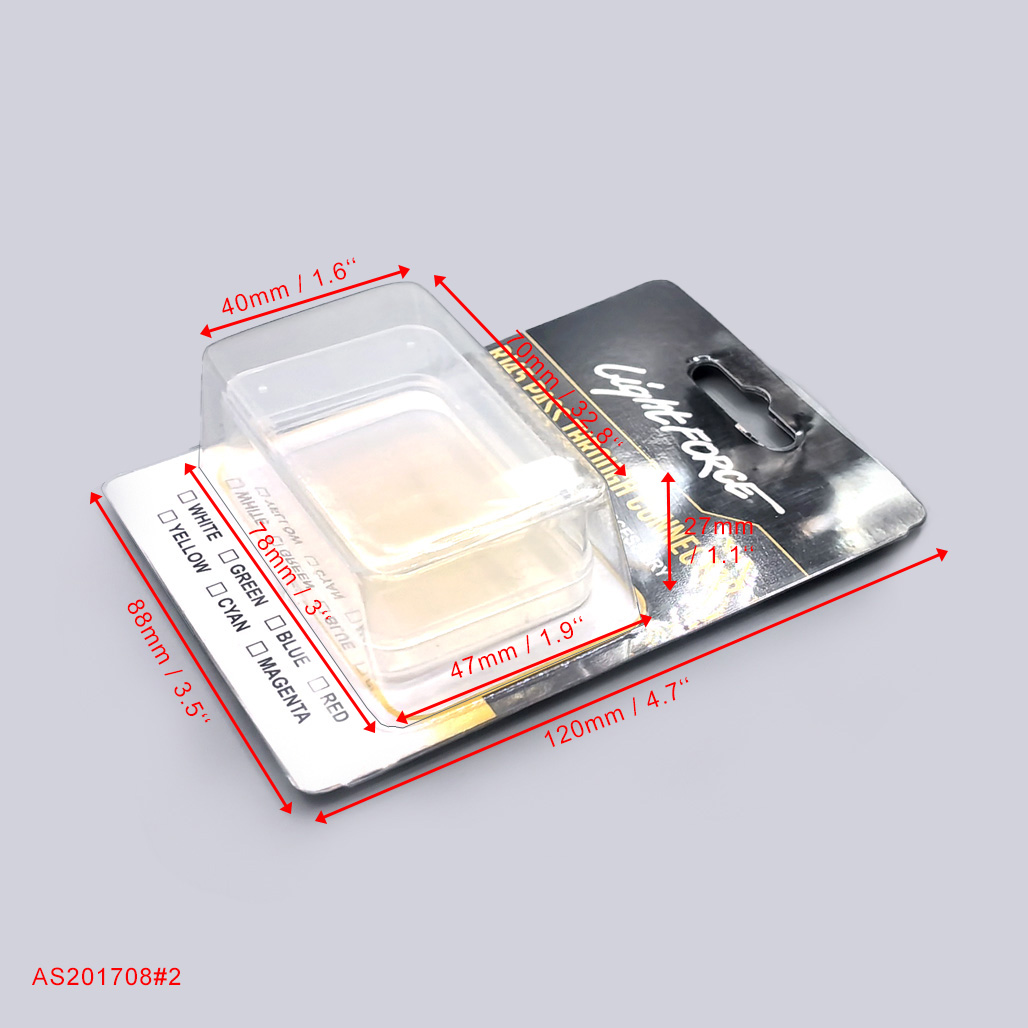

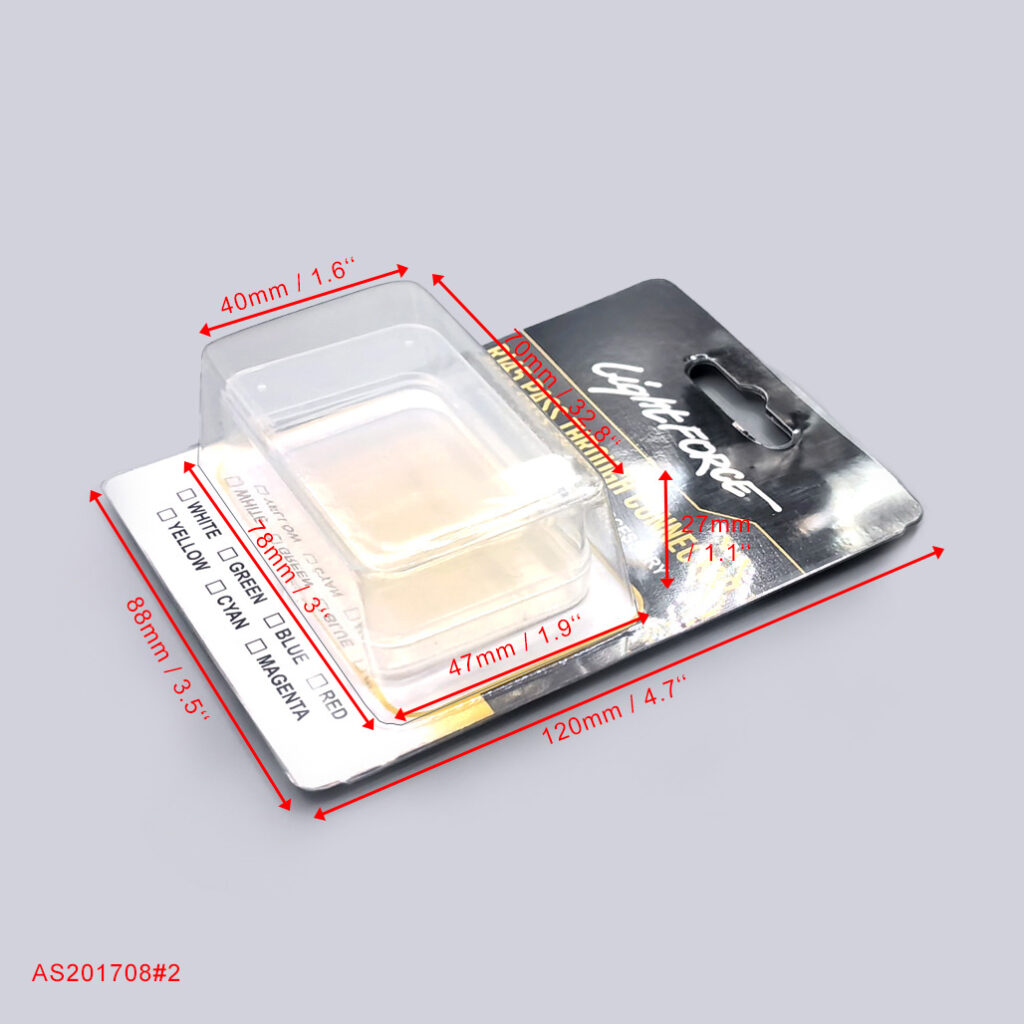

Bubble wrap packaging 1. Bubble wrap packaging is made of transparent materials, mainly PVC, PP or PET. - It can directly replace paper to make boxes or be used in conjunction with cards to form.

- It can be used inside packaging to secure products, known as blister inserts.

- Bubble wrap packaging can be printed using screen printing, conventional printing, or hot stamping.

- Machine printing is possible, but the printing cost is relatively high, so screen printing is generally used for small-scale production.

OPP bag 1. OPP bag is made of oriented polypropylene and is a type of plastic, essentially a plastic bag. - Products are usually placed in OPP bags before being packed into outer boxes to appear clean and hygienic.

- Other materials include PP bags and PE bags.

- The characteristics of OPP bags are high transparency, brittleness, and the ability to print various patterns or punch holes according to customer needs.

EVA (ethylene vinyl acetate) 1 EVA is a copolymer of ethylene and vinyl acetate, and products made from it have characteristics such as softness, shock resistance, slip resistance, and strong compressive strength. - Used for packaging and interior decoration, fixing and protecting products.

- EVA has multiple colors to choose from, and the surface can be covered with velvet or velvet to enhance visual appeal.

Foam (PS for short) 1 Foam is a kind of porous material, which has excellent elasticity. - Used for packaging and interior decoration, fixing and protecting products.

- foam has a variety of colors. It is usually used directly without additional processing.