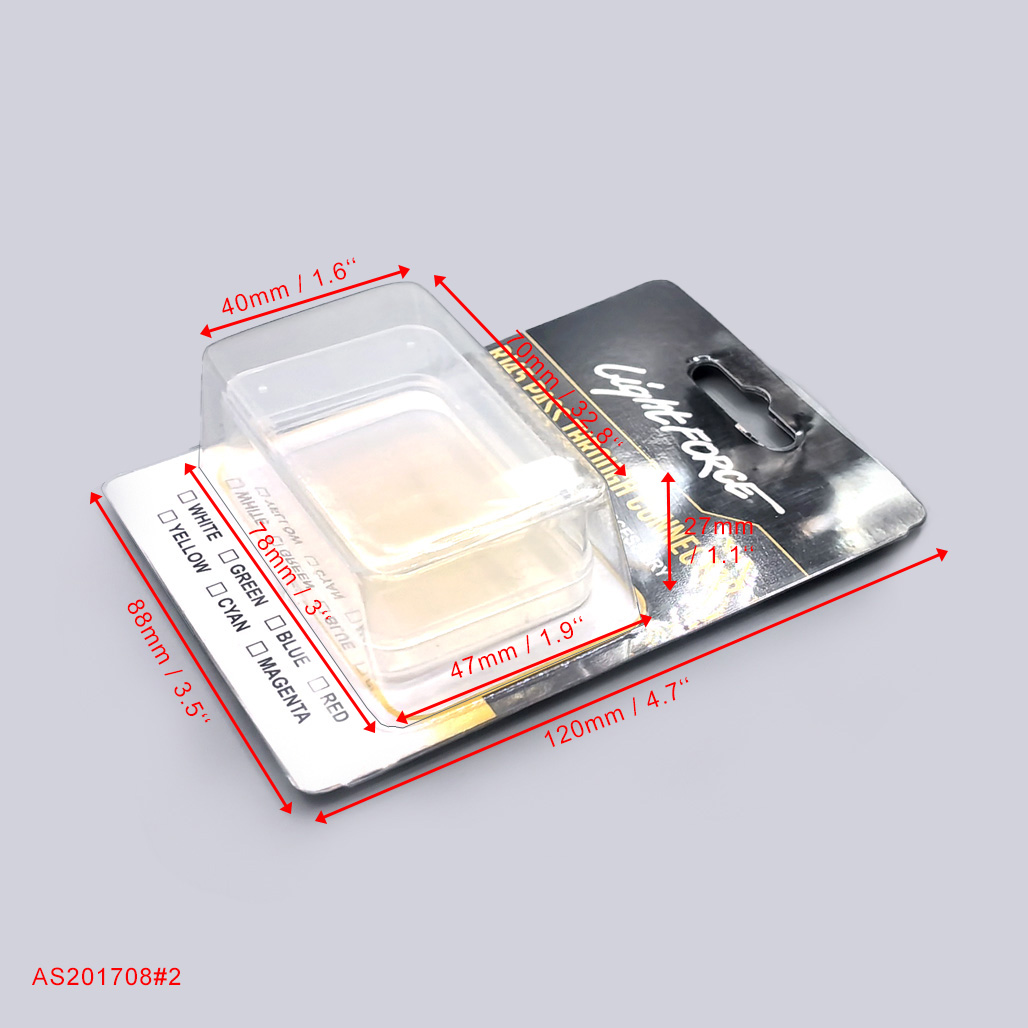

Introduction to vacuum forming materials: Vacuum forming is a thermoplastic processing technology mainly used to make various packaging containers and components. Blister materials usually use plastic sheets such as polypropylene (PP) and polystyrene (PS), which can be softened by heating and then transformed into the desired shape under the action of suction. Blister packaging has good transparency, toughness, impact resistance, and sealing properties, and is widely used in packaging for industries such as food, medical devices, and cosmetics.

2、 Advantages of vacuum packaging:

1. Good transparency: Vacuum packaging has good transparency, which can visually display the appearance and internal structure of the product. 2. Good toughness: Blister packaging has good toughness, is not easily broken or deformed, and can protect the integrity and safety of the product.

3. Good sealing: The sealing of vacuum formed packaging is good, which can effectively prevent the penetration of substances such as oxygen and moisture, ensuring the quality and shelf life of the product.

4. Low production cost: The production cost of vacuum formed packaging is relatively low, which can meet the needs of large-scale production.