Blister packaging contains a variety of products. They are hygienic, promote sales, and suitable for children’s use. You can find all the information about other advantages, application areas, and innovations of visual packaging here.

Blister packaging: wrapped in bubbles

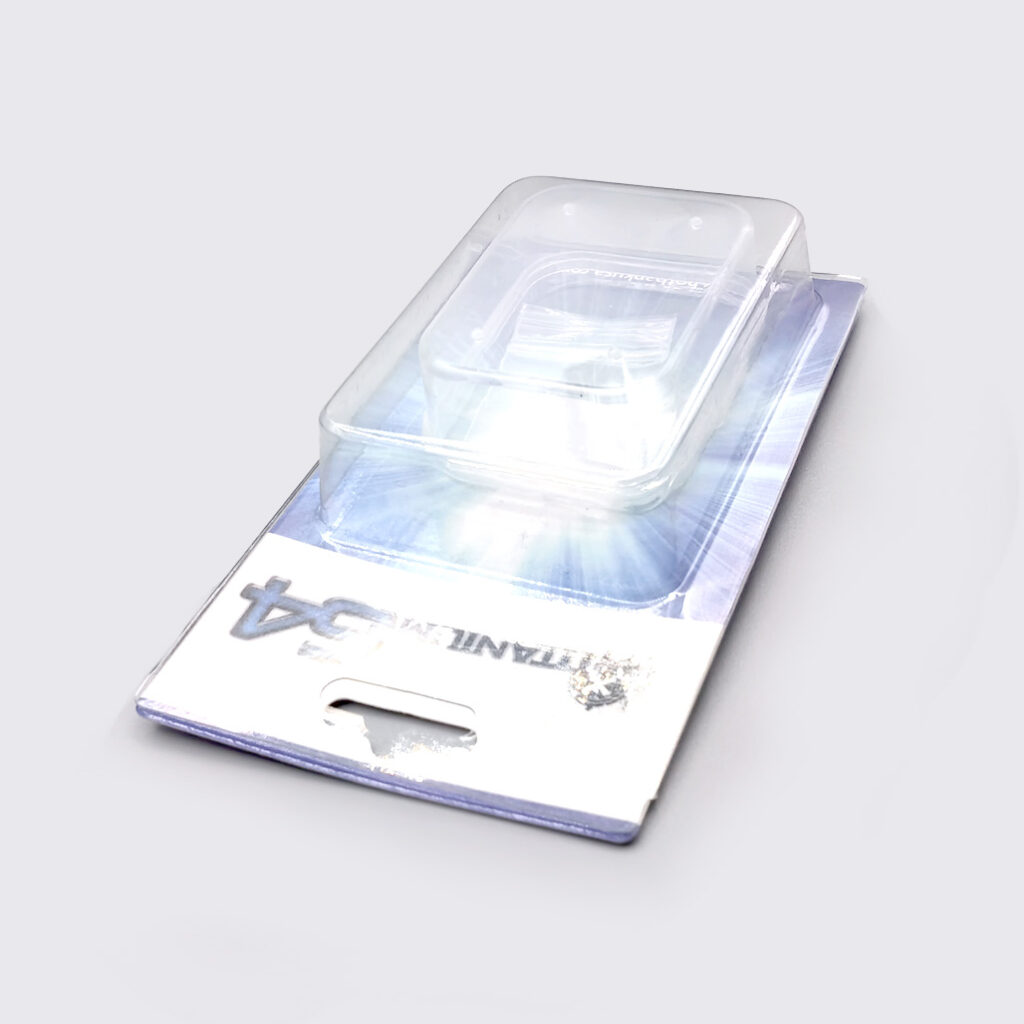

Blister packaging is a thin-walled transparent packaging, with the front usually made of plastic. The word “blister” originates from English and means “bubble”. The term “bubble wrap” refers to plastic film molded products typically containing bubble shapes. For example, tablets or other medications are placed below these bubbles. The back wall of these bubble wrap packaging is usually made of aluminum foil, but for non-medical products, it can also be made of plastic foil or sturdy cardboard.

The advantages of vacuum packaging

Vacuum packaging has developed into a successful model. There is a reason for this, as bubble wrap packaging has many advantages:

The blister packaging used for medical purposes ensures the highest hygiene standards as it can be sealed using special techniques. Dust particles and moisture have no chance.

This type of seal can prevent children from protecting the contents.

Other types of blister packaging, such as flip or clip blisters, are not sealed. For example, they are suitable for household products and have the advantage of being easy to open.

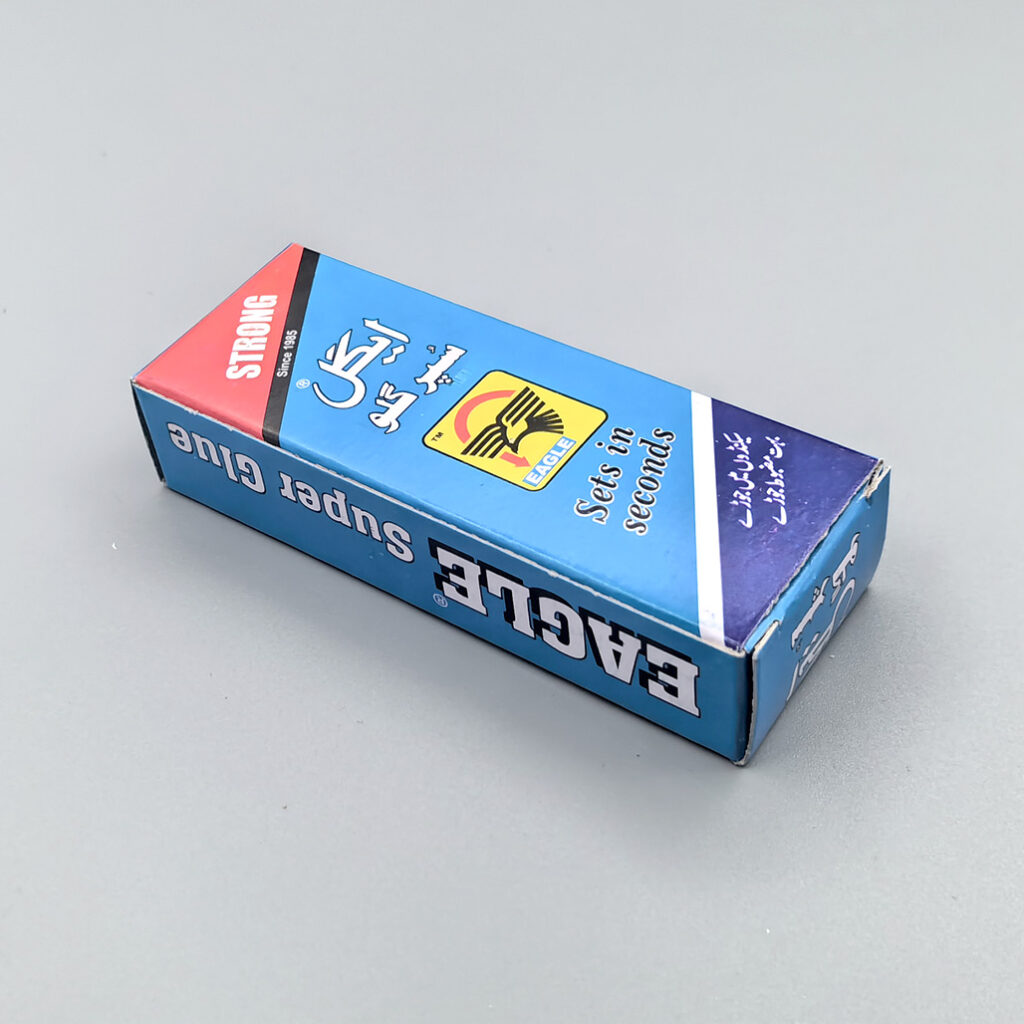

From a marketing perspective, blister packaging is essential because visibility means that packaged products are presented in an effective way.

The plastic film used for bubble wrap packaging has stretchability and can adapt to the contours of almost any product.

Bubbles make the packaging sturdy and protect the contents in case of collision or falling with other products.

The weight of vacuum packaging is relatively light.

Due to standardized brackets, they promote inventory of goods in retail and reduce inventory workload.

In addition to transparent display, cardboard or aluminum rear walls can also provide detailed product descriptions.

Blister packaging: This is where it comes into play

Blister packaging is essential, especially in the pharmaceutical industry. Not only drugs, such as contact lenses or toothbrushes, can also be protected in this way. Electronic manufacturers also prefer to use airtight and particle free blister packaging for sensitive components. For example, storage cards or USB sticks are usually packaged in this transparent packaging because they showcase their best advantages in this way due to their small size. Batteries and light bulbs are also packaged in bubble wrap. Visual packaging is also used in cosmetics, such as lipstick, shavers, or large eyed children’s toys.

Do you want to optimize your supply chain or find the perfect supplier in your region? Then register on our WLW platform.

Innovation: Intelligent and sustainable vacuum packaging

Intelligent packaging is one of the trends in the packaging industry. With the help of modern technology, bubble wrap packaging can help people not forget to take medication. Schreiner MediCharm’s intelligent packaging solution automatically records the quantity and type of medication removed. Then use an application or a separate reading device to transfer the stored data to the database. If patients forget to take medication or do not follow the recommended dosage, they will be informed of their improper behavior.

Green packaging

No matter what technology is used, traditional bubble wrap packaging has ecological issues. They are made of materials such as polyvinyl chloride (PVC) for bubble wrap foil and aluminum for the back wall. On the one hand, the production of these substances is very energy intensive, and on the other hand, they are based on fossil fuels such as crude oil and are usually not biodegradable.

However, at the same time, bubble wrap packaging mainly made of bioplastics has also emerged, which can meet the requirements of compostable materials. Other sustainable blister packaging does not contain any plastic at all. Folding boxes have replaced plastic, so the entire packaging can be disposed of with waste paper. The punching on the box ensures the visibility of such models.