Appreciation of Blister Packaging Design Cases

Common printing techniques and packaging materials

Common problems and solutions in PVC vacuum forming process

How to store vacuum formed packaging products correctly?

The differences in molds among the influencing factors of the vacuum forming process

Development prospects of vacuum vacuum formed packaging

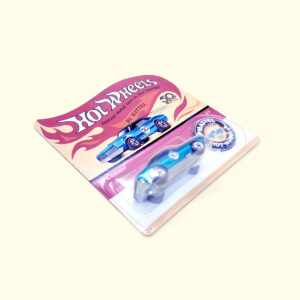

Blister packaging is a common form of packaging, which generally involves sealing and protecting irregular objects (such as toys, stationery, tools, daily necessities, etc.) with

Introduction to vacuum forming process: Vacuum forming is a plastic processing technology, which mainly involves heating flat plastic sheets to soften them, then vacuum adsorbing

Blister packaging refers to the production of plastic products using the vacuum forming process and the packaging of the products using corresponding equipment.Blister products are

We specialize in producing various types of vacuum formed packaging products and vacuum formed trays. The company adheres to the principle of “customer first, service

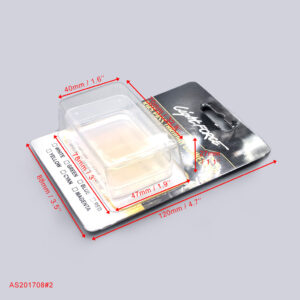

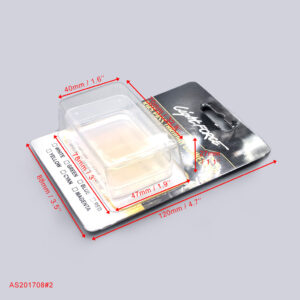

Full Card Blister is similar to fully sealed Blister. Plastic extends to accommodate the product and cover the entire card. The main difference lies in

Full Face Seal Blister packaging uses the same method as face seal Blister, but its characteristic is that the blister covers the entire surface of

Blister packaging “is a general term used to describe packaging that uses thermoforming processes. Thermoforming involves heating plastic sheets to a certain temperature to make

Blister packaging, as an innovative packaging method, has emerged in many fields with its unique advantages. 1、 What is vacuum packaging? Vacuum formed packaging, also

Shenzhen Kanmei Packaging Technology Co., Ltd. was established in 2001. It is a one-stop vacuum forming and color printing packaging solution service enterprise integrating research

Keymy Blister manufacturers can provide customized services according to customers’ specific needs, including product size, shape, and color customization, as well as the development of

The common materials for vacuum formed trays include the following: Features: It has good flexibility and transparency, and the price is relatively low. Application: Commonly

Shenzhen Keymy Packaging Technology Co., Ltd. was established in 2001. It is a one-stop vacuum forming and color printing packaging solution service enterprise integrating research

1、 Introduction to Packaging Since people began to produce and manufacture products gradually, they could not do without packaging materials, from the most traditional paper

Blister packaging is a widely used form of packaging in various fields, which uses the thermoforming process of plastic sheets to manufacture packaging containers that

Blister packaging refers to the production of plastic products using the vacuum forming process and the packaging of the products using corresponding equipment. Blister products

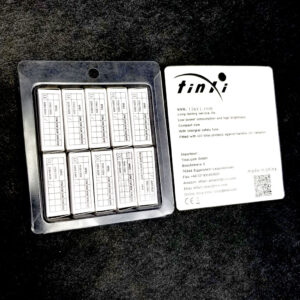

Blister is a packaging product made by heating, vacuum forming, cooling and other processes of PVC, PS, PET and other resin sheets in a vacuum

Blister packaging generally uses common plastic materials such as PET, PVC, PS, ABS, PP, PE, etc., which meet the same packaging requirements and are lighter

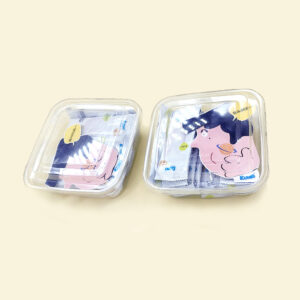

Every merchant always hopes that the things they produce are alive, wishing they could be living objects that can communicate with consumers on their own

Blister packaging refers to the production of plastic products using the vacuum forming process and the packaging of the products using corresponding equipment. The products

With the development of environmental protection trends, the requirements for plastic packaging are becoming increasingly strict. In addition to avoiding use, eliminating “excessive packaging”, and

With the development of environmental protection trends, the requirements for plastic packaging have become increasingly strict. In addition to avoiding use, eliminating “excessive packaging”, and

Vacuum forming is a plastic processing technology, which mainly involves heating flat plastic hard sheets to become soft, using vacuum adsorption on the surface of

Vacuum forming, also known as vacuum hot pressing, is based on the principle of pulling rolled sheets into an electric furnace oven and heating them

1. Blistering: A plastic processing technology that mainly involves heating flat plastic hard sheets to soften them, using vacuum adsorption on the surface of the

Vacuum packaging is a general term for plastic products produced using vacuum molding technology and packaged with corresponding equipment. The products mainly include: bubble shells,

Common thin film vacuum forming materials include PP, PET, PVC, PP+PP copolymer, and PE+PP copolymer. Sensory identification: This product is white and transparent, with higher

Vacuum forming is a plastic processing technology, which mainly involves heating flat plastic hard sheets to become soft, using vacuum adsorption on the surface of

Blister packaging products are a common type of plastic packaging product, widely used in industries such as food, cosmetics, and electronic products. Proper storage is

Blister packaging contains a variety of products. They are hygienic, promote sales, and suitable for children’s use. You can find all the information about other

1、 PVC sheets have high toughness and are not easy to burn. When burned, chlorine gas is produced, which has a certain impact on the

Rich product variety to meet diverse needs As the source manufacturer of vacuum molded products, we are committed to providing customers with diverse product choices.

The design of vacuum packaging is to ensure that the product can be securely placed inside the packaging, while providing protection and display effects. Designing

Blister packaging is a common form of packaging that typically uses plastic materials. After being heated at high temperatures, plastic sheets or films are softened

Shenzhen keymy Packaging has 20 years of experience in blister packaging manufacturing and 18 years of experience in cross-border e-commerce. A grassroots entrepreneur who started

Vacuum packaging is a general term for plastic products produced using vacuum molding technology and packaged with corresponding equipment. Vacuum molded products are mainly made

Vacuum molded products are processed using plastic, and the principle of product generation is to heat and soften the flat plastic hard sheet material, then

The main classification of blister covers or blisters A、 Ordinary thin vacuum molded products with a thickness of 0.14-5.0m are mainly made of various materials

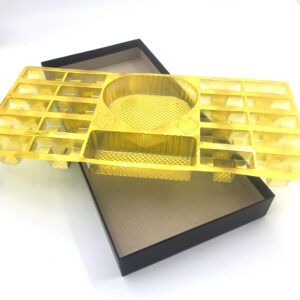

The relevant molds for the blister cover (bubble shell) are mainly made of yellow blister hand board gypsum powder. If drawings are provided, the stone

Folded blister packaging, also known as double buckle blister, is a customized blister manufacturer that looks at the beauty of packaging products. When producing double

Vacuum plastic packaging, also known as containerless packaging, can save a lot of packaging raw materials, reduce packaging waste, and meet the requirements of moderate

01 Overview of vacuum molding process Vacuum forming technology is one of the most commonly used forming methods in plastic packaging, which is a forming

Produce plastic products using vacuum molding technology and package them with corresponding equipment. This process is called vacuum packaging. The main advantages of vacuum packaging

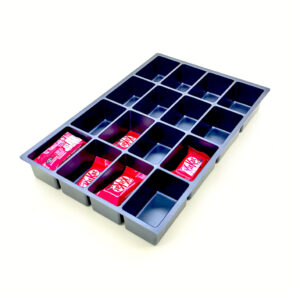

Usage classification Blister packaging: a general term for plastic products produced using the vacuum molding process and packaged with corresponding equipment. Blister packaging products include:

Fruit vacuum box is a plastic processing technology, which mainly involves heating flat plastic hard sheets to soften them, using vacuum adsorption on the surface

Vacuum packaging is a general term for plastic products produced using vacuum molding technology and packaged with corresponding equipment. Chinese name Blister packaging Processing technology

Vacuum moldingA plastic processing technology, mainly based on heating flat plastic hard sheets to become soft, using vacuum adsorption on the surface of the mold,

Folding blister packaging refers to one of the types of blister packaging, also known as double buckle blister, which mainly uses materials such as PVC,

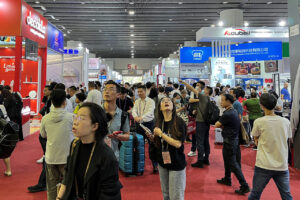

The second session of the trade fair focuses on the theme of “Big Home” More than 150000 overseas buyers attended the meeting on the first

What are the advantages of vacuum packaging?

Vacuum forming manufacturing process equipment

The application of vacuum molding technology

The knowledge of printing and packaging technology

How are increasingly beautiful food packaging designs made?

What are the advantages of vacuum packaging?

How to store blister packaging products correctly?

Blister packaging is widely used in fields such as food, medical devices, cosmetics, and electronic products. Here are some application cases: Food: Vacuum packaging is

The influencing factors of vacuum packaging production process

Blister packaging is a common form of packaging that transforms plastic sheets into the desired shape through processes such as heating and suction, and then

The main production process of vacuum molded products

The main production process of vacuum molded products (1)

Vacuum plastic packaging, also known as containerless packaging, can save a lot of packaging raw materials, reduce packaging waste, and meet the requirements of moderate and reduced packaging advocated globally.

The working principle of positive and negative pressure vacuum molding machine

Vacuum forming materials and vacuum forming molds

Vacuum forming is a plastic processing technology, also known as vacuum forming or hot forming. It is a product formed by heating and softening plastic

Simple process flow for positioning vacuum molding

Blister Clamshell packaging custom Blister Clamshell packaging

The main production processes of vacuum molded products include demolding, sheet pulling, punching, edge folding, punching, packaging, etc. The following will be introduced separately.

The 6th-FL, Building A, No. 29, Jiangjunmao Industrial Zone, Wulian, Longgang, Shenzhen, Guangdong, P.R.China 518172