1. Blistering: A plastic processing technology that mainly involves heating flat plastic hard sheets to soften them, using vacuum adsorption on the surface of the mold, cooling them, and forming them.

2. Blister shell: Using vacuum molding technology, transparent plastic hard sheets are made into transparent plastic with specific raised shapes, which is covered on the surface of the product to protect and beautify it.

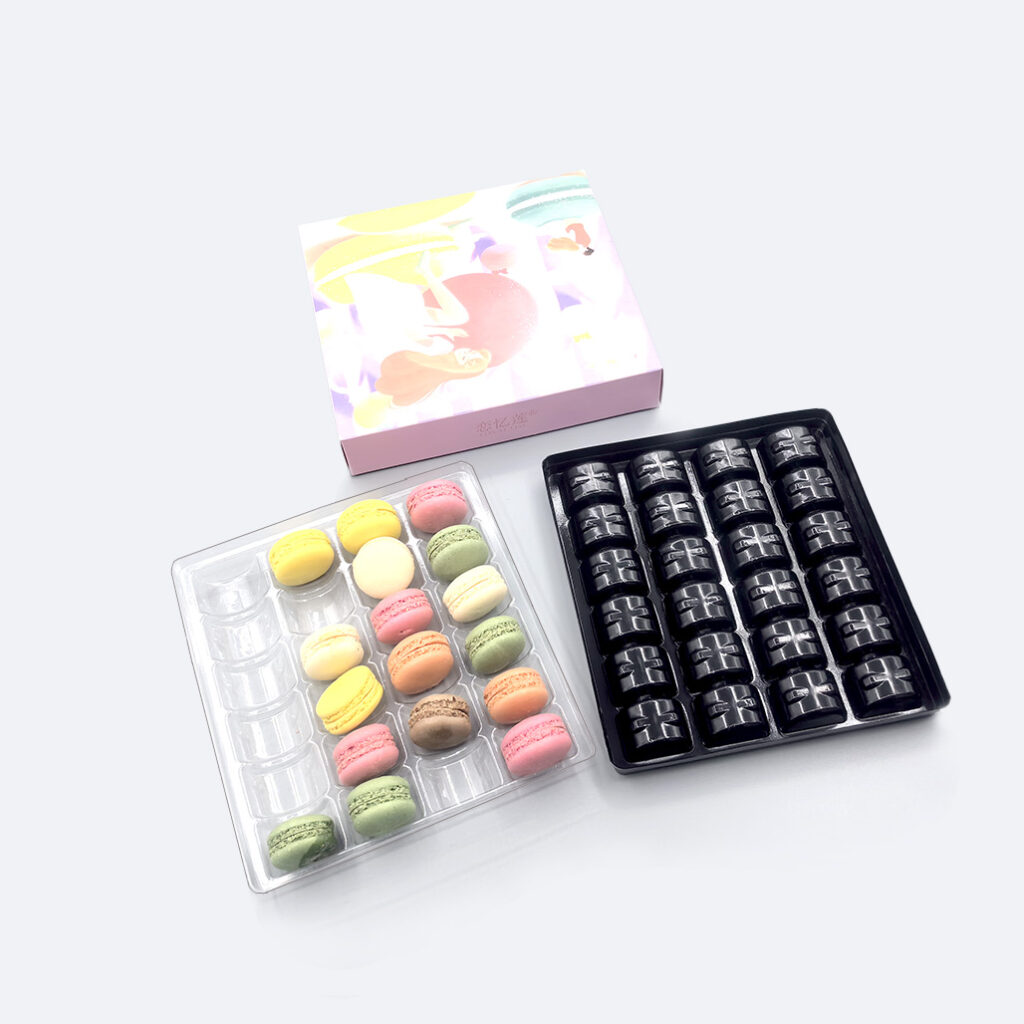

3. Vacuum tray: also known as plastic inner tray, uses vacuum molding technology to make plastic hard sheets into specific grooves of plastic, and places the product in the grooves to protect and beautify the product

- Flocking blister: It is a type of blister tray made of special materials, which glues a layer of plush material on the surface of ordinary plastic hard sheets to give the tray a plush texture, used to improve the quality of packaging products.

- Vacuum forming: It is commonly known as vacuum forming, which uses a vacuum forming machine to adsorb the heated and softened plastic hard sheets onto the surface of the mold, and after cooling, form a concave convex shaped plastic.

- Vacuum cutting: After vacuum forming, plastic products are cut into individual pieces using a punching machine to cut large sheets of material into individual products.

- Blister Folding: There is a type of blister packaging called card insertion packaging, which requires folding the three edges of the blister to the back using a folding machine, so that in the next packaging process, the paper card can be inserted into the folding edge to form a card insertion packaging.

- Vacuum sealing: It is a vacuum sealing process that uses a sealing machine to heat seal paper cards coated with vacuum oil and bubble shells together to form vacuum packaging, also known as paper plastic single-sided hot pressing.

- High frequency blister sealing: It is a blister packaging process that uses a high-frequency machine to generate high frequencies and bond the blister shells together to form a double blister shell packaging, also known as high-frequency double-sided heat sealing.