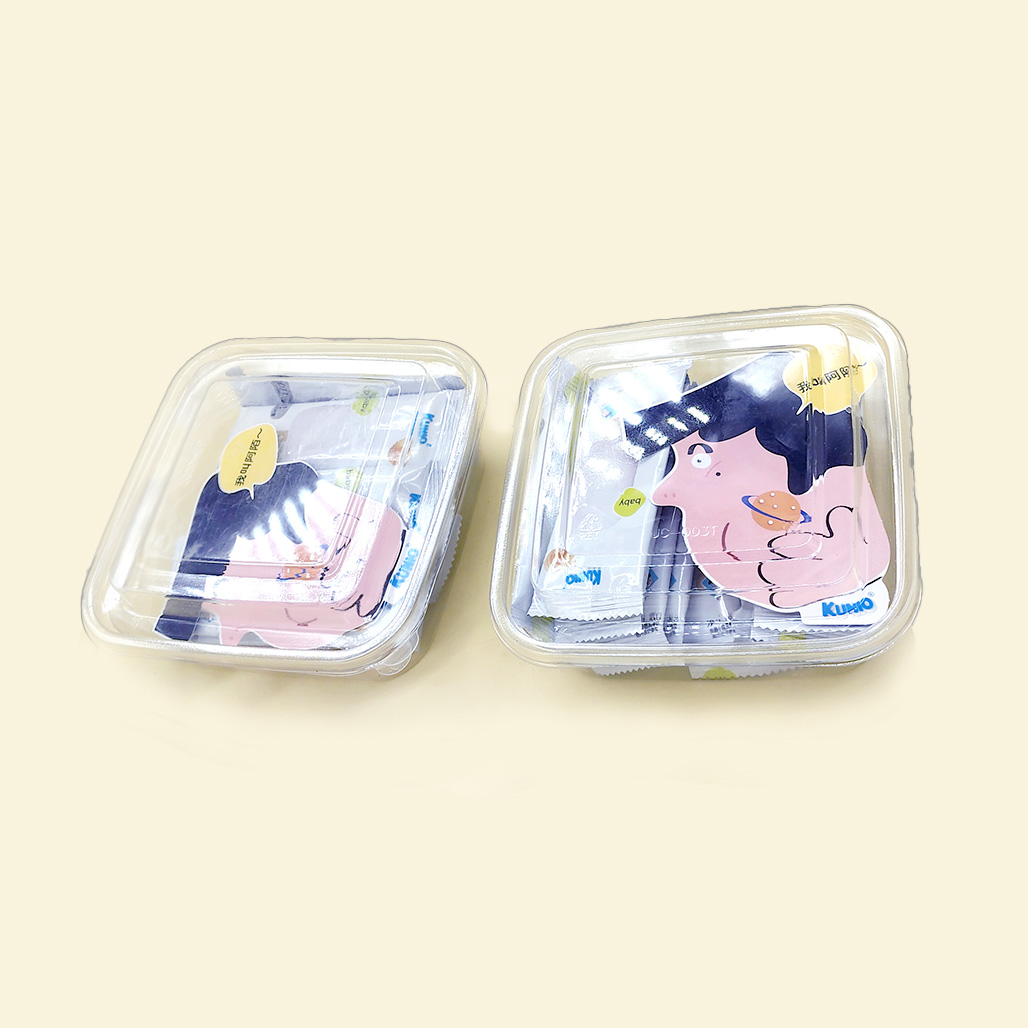

Folded blister packaging, also known as double buckle blister, is a customized blister manufacturer that looks at the beauty of packaging products. When producing double fold blister packaging products, the mold is equipped with buckles, and the workmanship is very fine. The products are made with two straight buckles on both ends. Folding blister packaging can not only better package products, but also make them look more beautiful. If necessary, staples can also be added.

The production of folding vacuum plastic molds, using the mold forming method to form plastic parts with high dimensional accuracy on the outer surface, is generally used for plastic parts with small forming depths. If the depth of the plastic part is large, especially for small plastic parts, the bottom will become noticeably thinner. The vacuum forming of the concave mold with multiple cavities saves materials compared to the same number of convex molds because the distance between the concave mold cavities is closer.

For vacuum formed parts that require the bottom thickness not to be reduced, convex molds can be used for vacuum forming. The principle is to first heat and soften the tightened plastic sheet under a heater. When the heated sheet first contacts the convex mold, it is cooled and loses its thinning ability. When the material continues to move downwards until it fully contacts the convex mold; Then vacuum is applied, and the edges and surrounding areas are formed by thinning. Convex mold vacuum forming is often used for thin-walled plastic parts with raised shapes, and the dimensional accuracy of the inner surface of the formed plastic parts is relatively high.