The design of vacuum packaging is to ensure that the product can be securely placed inside the packaging, while providing protection and display effects. Designing blister packaging based on product shape is a crucial step in ensuring that the packaging can tightly adhere to the product, providing appropriate support and protection. Here are a few steps on how to design vacuum packaging based on product shape:

- Understand the shape of the product

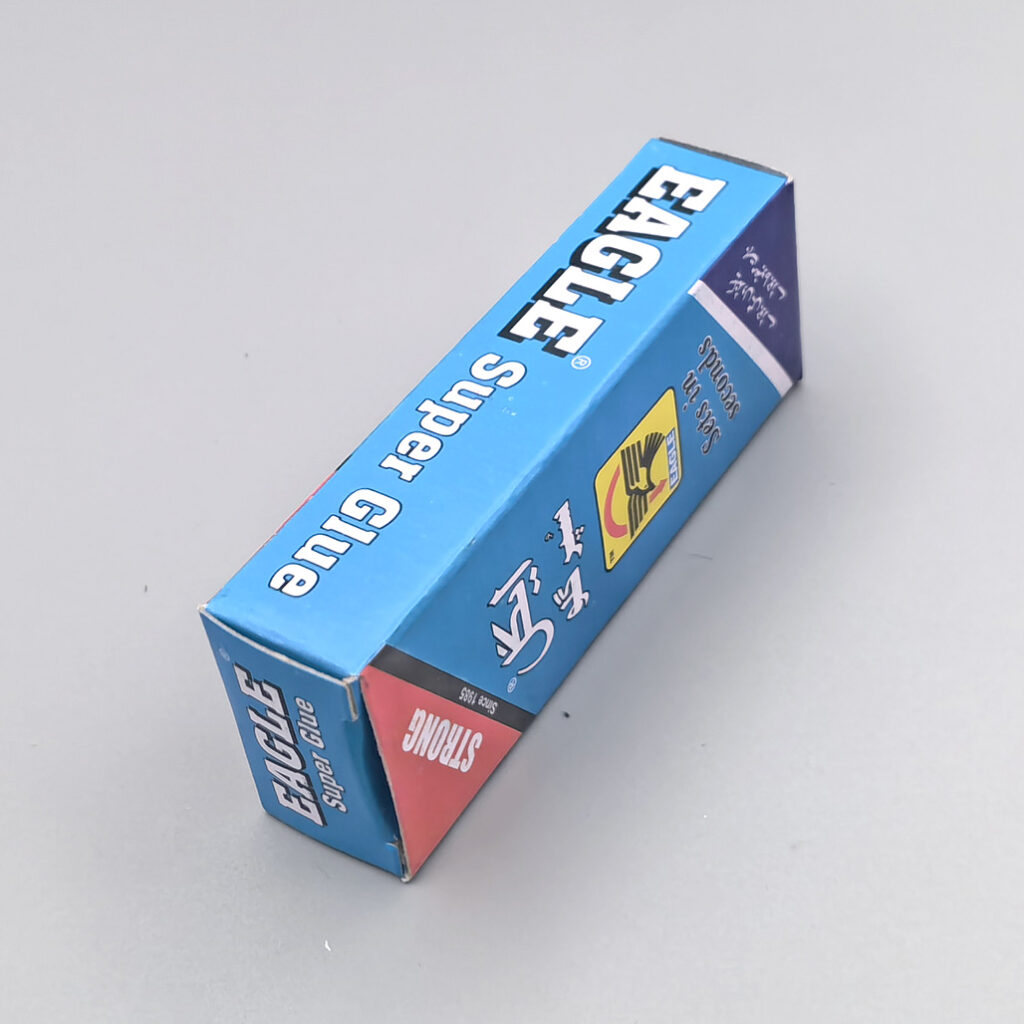

Firstly, carefully observe and analyze the shape of the product. Understand the length, width, height, curves, edges, and other characteristics of the product. This will help you determine which blister packaging shape is most suitable for the product.

- Choose the appropriate shape for vacuum packaging

Based on the shape of the product, select the most suitable blister packaging shape. For example, if the product is a rectangular shape, you may need a rectangular blister packaging. If the product has a curved shape, you may need a molded vacuum packaging. Ensure that the vacuum packaging tightly wraps the product while leaving enough space to adapt to changes in the product.

3. Consider the stability of the product When designing vacuum packaging, it is important to ensure that the product remains stable inside the packaging. If necessary, you can add support structures such as support columns or plates to the blister packaging to prevent the product from moving or shaking during transportation.

- Optimize packaging design

Optimize the design of vacuum packaging as much as possible while ensuring product protection and stability. Consider reducing unnecessary space and materials to lower packaging costs and improve environmental friendliness. At the same time, ensure the attractive appearance of the vacuum packaging to enhance the market appeal of the product.

- Consider production process and mold manufacturing

When designing vacuum packaging, it is also necessary to consider the feasibility of production technology and mold manufacturing. Ensure that the designed vacuum packaging can be manufactured using existing production processes and molds, and meet production efficiency and cost requirements.

- Conduct prototype testing and verification

Before formal production, make a prototype of vacuum packaging and conduct testing. Place the product into the prototype and check for tight fit, stability, and compliance with protection requirements. Adjust and optimize according to the test results until all requirements are met.

- Combining brand and design elements

In addition to basic shape and functional requirements, vacuum packaging can also incorporate brand and design elements to enhance the brand image and market appeal of the product. For example, adding the company’s logo, slogan, or unique design pattern on blister packaging.

In summary, designing vacuum packaging based on product shape requires consideration of multiple aspects, including product shape, stability, production process, mold manufacturing, as well as brand and design elements. By considering these factors comprehensively, a practical and attractive vacuum packaging can be designed to meet the packaging needs of the product.