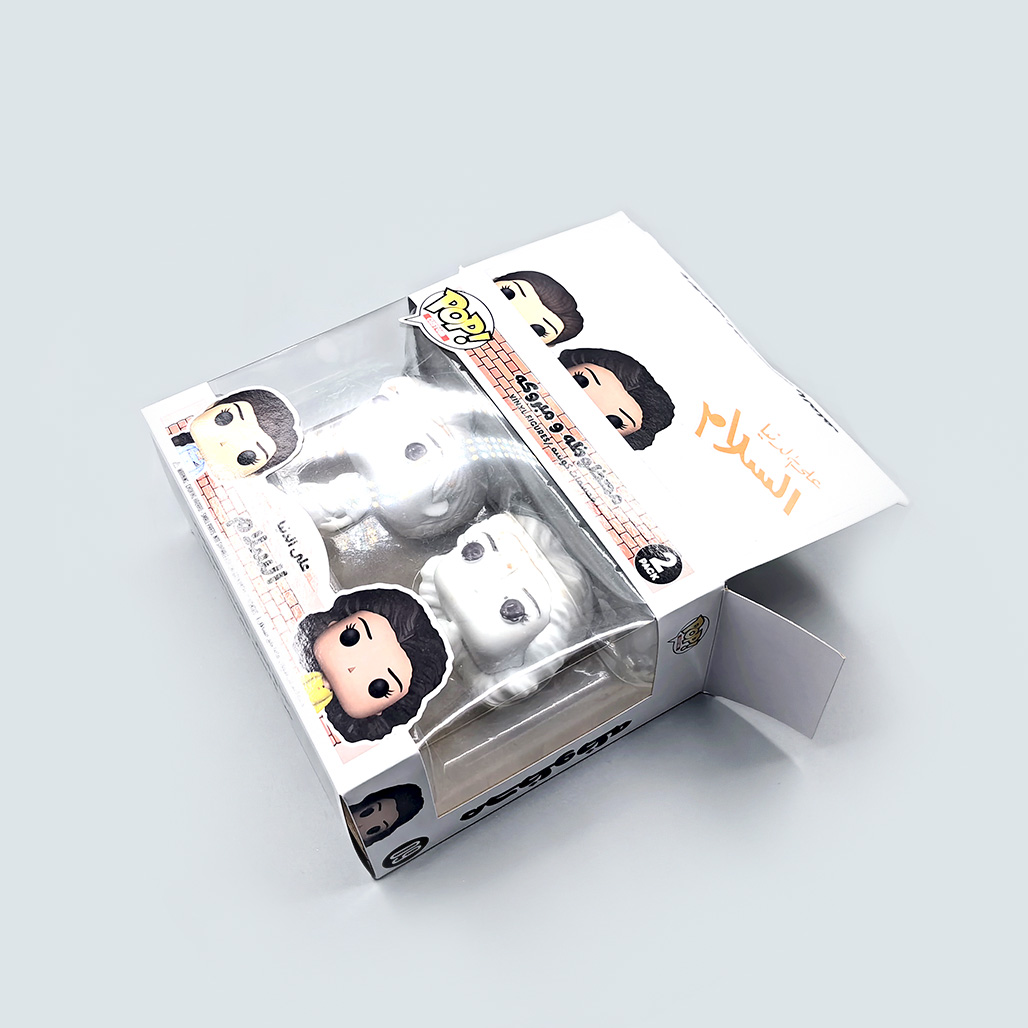

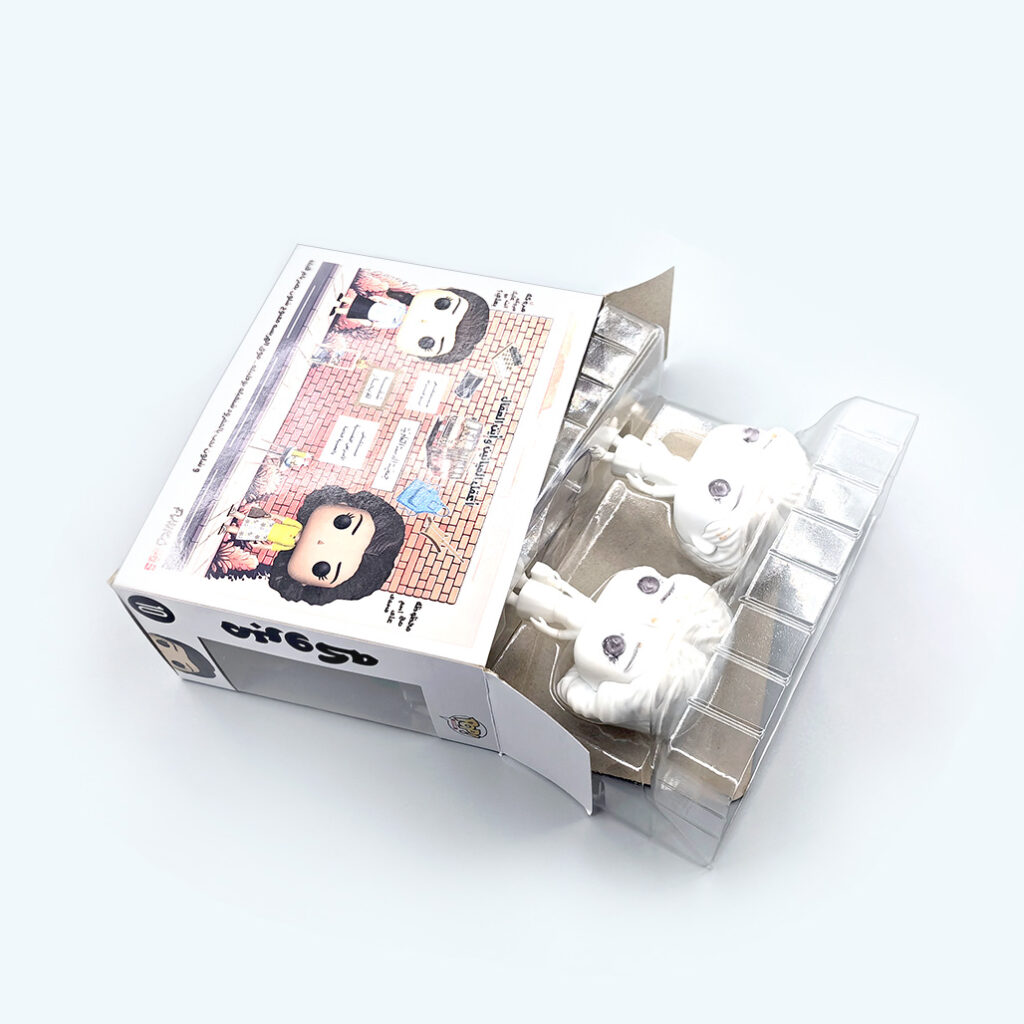

Vacuum forming is a plastic processing technology, which mainly involves heating flat plastic hard sheets to become soft, using vacuum adsorption on the surface of the mold, cooling them, and forming them.

Used for packaging, vacuum molding is trustworthy

The numerous types of vacuum molded products produced by the vacuum molding process are widely used in industries such as plastic packaging, lighting, advertising, and decoration. Vacuum molded products are mainly made of high-quality PVC PET、PP、PS、GAG、 Made of various plastic materials such as flocking.

Vacuum molded products are almost suitable for packaging various products. When packaging high-end and various specifications of electronic, stationery, toys, hardware, food, daily chemical gifts, and handicraft products, the presence of vacuum packaging is indispensable. Blister packaging has gained unanimous recognition from manufacturers and consumers for its excellent quality, affordable price, and beautification of products.

Why do so many products love to use vacuum packaging?

one

Blister packaging can increase the price and image of the product itself, while also having a shaping and dissemination effect, which has a significant impact on the brand image and popularity of the enterprise.

Two

Blister packaging aims to showcase and protect products. The packaged products are mostly small commodities that can be placed or hung on supermarket shelves, allowing your products to be perfectly displayed in front of customers and promoting product sales.

The purpose of vacuum packaging is to separate, shock-absorbing, and accompany. The packaged products are mostly electronic, IT, industrial parts, toys, stationery, food, handicrafts, cosmetics, etc. It can package many but small products, making the products more aesthetically pleasing as a whole.