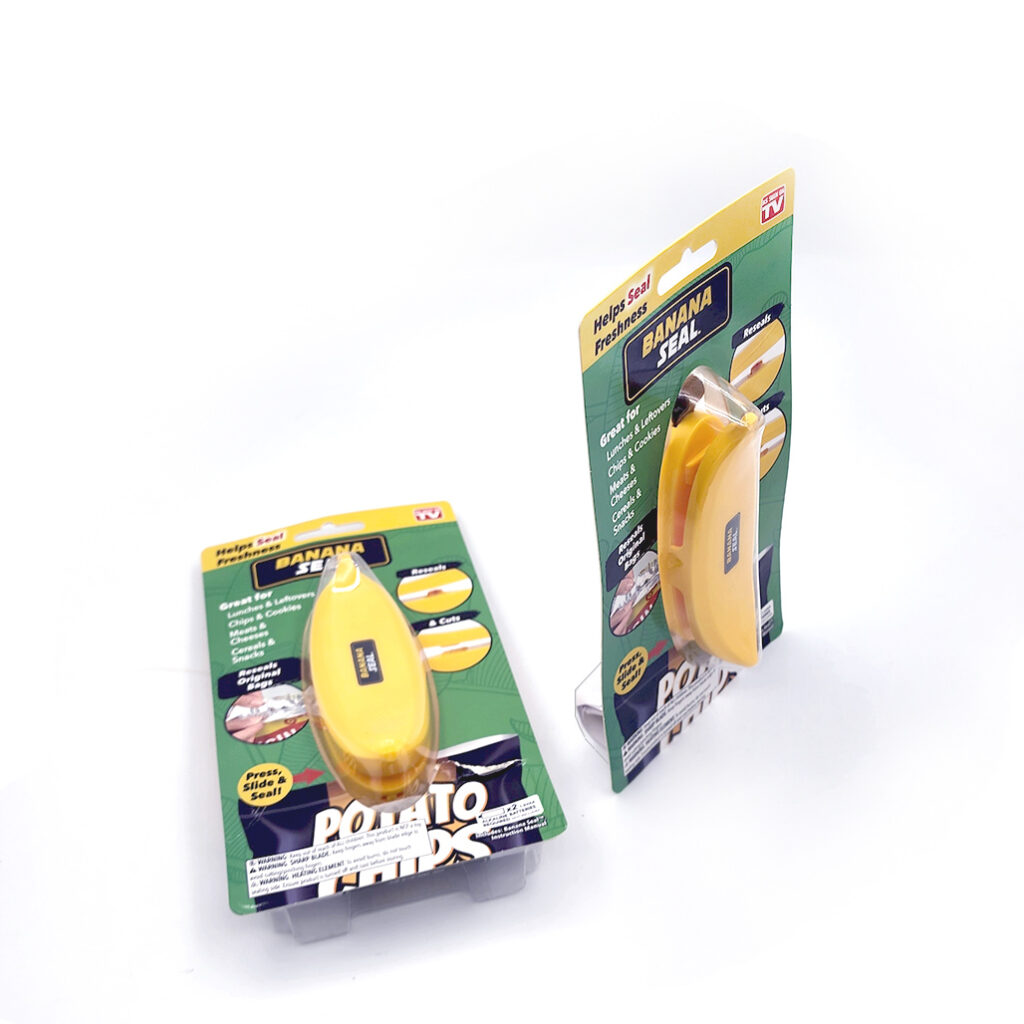

Blister packaging is a common form of packaging, which generally involves sealing and protecting irregular objects (such as toys, stationery, tools, daily necessities, etc.) with PVC or PET foam shells, and then bonding the foam shells with paper cards to form a complete, regular, and transparent packaging form. There are four advantages: neat appearance, convenient storage and transportation; Clear at a glance, easy to sell; Barrier protection, not contaminated; Minimize the use of plastic to the greatest extent possible. According to calculations, vacuum packaging can save one-third or even more of plastic packaging usage, making it a form of replacement for plastic packaging. Blister packaging is the process of combining two materials together, which poses some technical difficulties.

The vacuum forming heat sealing packaging process is to press the bubble shell and the paper card coated with vacuum forming oil, and use electric heating or high-frequency heating to heat the bubble shell and paper card. The softened bubble shell is firmly bonded to the melted vacuum forming oil. After cooling, the bubble shell, vacuum forming oil, and paper card are integrated to complete the vacuum forming packaging process. As shown in Figure 1, there are five layers of vacuum formed packaging.