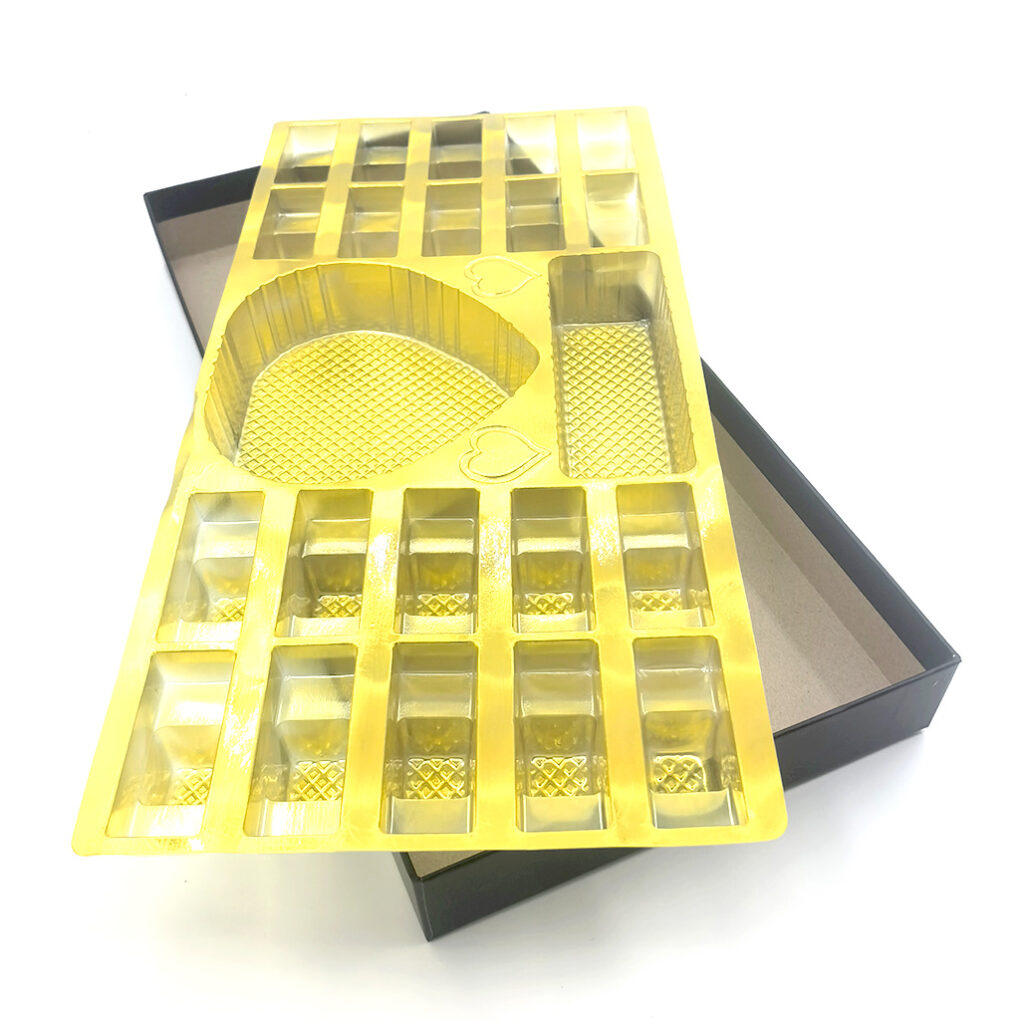

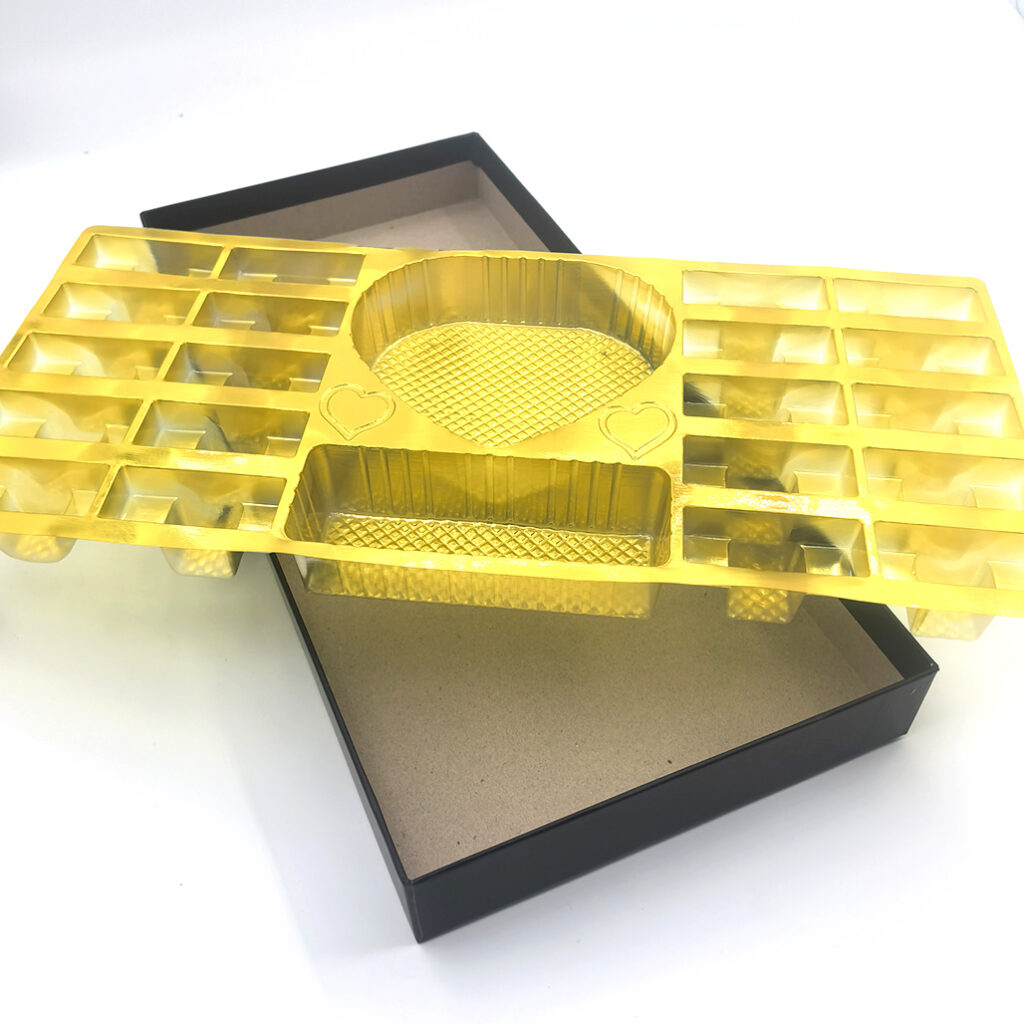

Blister is a packaging product made by heating, vacuum forming, cooling and other processes of PVC, PS, PET and other resin sheets in a vacuum forming machine, shaping them according to the shape of the mold, then stamping them into individual products with a die on a punch press, and finally using folding, punching and other processes. This type of packaging product has the characteristics of cheap materials, simple processes, low investment, and considerable profits. It is suitable for packaging small daily necessities, small appliances, toys, and other goods, and is not suitable for packaging products with high buffering requirements and heavy weight.

1、 The main production process of vacuum formed products

The main production processes of vacuum formed products include molding, pulling, punching, folding, punching, packaging, etc., which will be introduced separately below.

- Mold making

After the customer confirms the sample, the gypsum mold used for sampling is used as the mother mold. After electroplating copper, the mold for production is made according to a certain quantity and position, which is called mold making. There are three types of conventional molds: gypsum molds, copper molds, and aluminum molds. Gypsum molds are mainly used for sampling and generally cannot be used for mass production. Their production time is usually 24 hours. Copper molds are electroplated with a layer of copper on gypsum molds, which enhances their strength and wear resistance. They are cost-effective and are the most commonly used molds in production. The production cycle is generally 100 hours, with a minimum of 3 days, and the service life is about 100000 pieces. When the quantity reaches 1 million or more, aluminum molds can be made. Aluminum molds are made of pure aluminum, which is costly and requires machine processing. The general molding time is 3 days. Aluminum molds have good production quality, fast heat dissipation, high product accuracy, and long service life. If customers require precise products and copper molds cannot meet the accuracy requirements, even if the quantity is small, aluminum molds must be made.

- Pull tab

The vacuum forming machine heats, vacuum forms, and cools the raw material coil into predetermined sizes, which is the main process of vacuum forming. The length of the pull tab is between 600-1170mm according to actual needs. Different materials and thicknesses have varying requirements for temperature regulation, requiring personnel with considerable experience when starting up. The adjustment test for the pull tab usually consists of 3 pieces. The length of each insertion of the vacuum forming machine is called the pulling length, which can be determined according to the length of the mold layout.

- Punching machine

The products that are pulled out are usually multiple products (according to the number of mold rows), which need to be punched into a single product on a punch press with a die. This process is called a punch press.

- Folding edge

For some products that require folding the corners of both or multiple sides of the vacuum formed product to insert the paper card, this process needs to be added. This process is completed by a folding machine.

- Punching

If the customer has special requirements, this process should be added when punching holes on the vacuum forming.

- Packaging

Attention must be paid to the packaging of vacuum formed products, and the appropriate packaging method should be determined based on the strictness of customer requirements, product materials, shape, etc. If the customer has no special requirements, the method of packing and packaging with plastic bags can be used. For products that are white or brightly colored, prone to scratches or cannot stick to dust or fingerprints, gloves are often worn during production.

2、 Blister material

The commonly used vacuum forming materials include PVC (about 50%, density of 1.36g/cm3), PS (about 30%, density of 1.06g)/

Cm3), PET (approximately 10%, density of 1.39g/cm3), PP (approximately 10%, density of 0.92g)/

cm3)。

The maximum thickness of PVC is generally 0.8mm, while PS can reach up to 1.2mm. Films with a thickness exceeding this range are difficult to pull and can easily cause damage to equipment.

The color of materials is generally determined according to customer requirements, such as PANTON color codes, color matching drafts, and color separation standards. Customers can also specify approximate colors and provide them based on product inventory. If the customer has no specific requirements, colorless, transparent, and easily producible materials can generally be used. If ordering colored sheets, it is generally necessary to order at least 2t before customization can be made. The density of colored materials is higher than that of transparent materials. The flocking material is generally made of PS material with lower density. If the density is high, it is easy to produce some areas without fibers on the surface after stretching. Generally, materials with bright colors are easier to produce and do not have high packaging requirements. Scratches on light colored materials are easily visible, and strict packaging requirements are required. Generally, flocking materials need to be prevented from scratching or creasing. When products are put together, friction may occur in tight contact areas, resulting in whitening. For places like this, special attention should be paid when packaging. If strict requirements are required, methods such as using plastic bags and separating copy paper should be considered for protection. Plush materials are generally ordered according to their length (in meters).

The characteristics of materials generally include anti-static properties. Anti static materials are made by soaking or adding anti-static components, with the latter method having long-lasting anti-static performance. The static electricity value of anti-static materials can generally reach 106-1012 Ω. In addition, there is environmental friendliness, with APET being the most environmentally friendly and PVC being recyclable. Generally speaking, the thicker the material, the longer the heating time required, and the slower the production speed; The thinner the material, the faster the production speed, but the length of a roll is also longer.

3、 Blister mold

Blister molds can be divided into lower molds, upper molds, and knife molds, which will be introduced separately below.

- Lower mold

The lower mold is an essential tool in vacuum forming production. According to different production processes and materials, it can be divided into gypsum molds, copper molds, and aluminum molds. When customers provide samples, drawings, or physical objects, it is necessary to make gypsum molds with added samples. Gypsum molds are made by adding water to gypsum powder, shaping it into a certain shape, dehydrating it, and hardening it into a mold. Materials and tools such as gypsum powder, drill bits, sandpaper, and wooden boards are needed. Because it is handmade, there will be a deviation of about 2mm in the drawings. After gypsum molding, it can be directly sampled and is not suitable for large-scale production. Gypsum molds can be modified after forming, and it is generally easier to make them smaller than larger. After the customer confirms the sample, the gypsum mold used for sampling can be used as the seed mold (mother mold), and multiple sub molds can be produced according to production needs. The size of the sub mold does not deviate significantly from the seed mold, usually around 0.5mm. After the lower mold is made, it needs to be fixed on a plywood with a thickness of about 8mm, and can be installed on the mold basin during production. When the heated sheet passes through the mold, it is sucked by the vacuum pump and attached to the lower mold to produce a product with the same shape as the lower mold.

- Upper mold

Sometimes, relying solely on vacuum suction is not enough to shape the product, and a certain amount of external force needs to be applied to make the upper mold. The upper mold is not necessary for all products, but depends on the production needs. When testing the machine, if the vacuum forming is not good and needs to be molded, the operator will make the upper mold according to the shape. The material for the upper mold is usually iron or wood, and the contact surface with the product needs to be wrapped with a softer sponge or velvet cloth.

- Knife mold

Generally, there are multiple the first mock examination for blistering. After forming, the finished product needs to be cut according to the size and shape of the product. The process of cutting the finished product is a punch, and the mold used is a knife mold. Knife molds can be divided into three types based on materials and manufacturing processes: iron knives, wood sample knives, and laser knife molds. Among them, the iron knife is thicker and can generally be made into more regular shaped knife molds, such as rectangles, ellipses, etc., which are not suitable for making overly curved shapes. The blade used for the wooden sample knife, which is the beer machine knife mold used for the color box, needs to be stacked with a certain number of layers according to the height of the product, and sometimes a cushion is also needed. For knife molds that require high precision, laser knife molds can be made, similar to wooden sample knives. After the knife mold is made, the product that needs to be positioned usually needs to be fixed in the knife mold as a finished product for easy positioning during product punching. Products that do not require positioning, such as edgeless vacuum formed products, are generally modeled with an iron knife.

4、 Dimensions and tolerances

The size of vacuum forming can be divided into three types: copying according to customer samples (called replication), making molds according to drawings, and designing according to the actual product. Because the shape of vacuum forming is generally customized based on the actual product, the shape is often irregular, and there are many dimensions that are inaccurate or cannot be marked during the drawing production, resulting in significant deviations during the drawing production. For accuracy, it is necessary to provide a physical trial installation. The size deviation of the product produced by sample replication is not significant.

The general thickness tolerance is 0.1mm, and the product deviation is ± 2mm. The main reasons for tolerance are:

- Deviation caused by manual molding. This deviation is generally less than 2mm.

- Deviation generated when replicating submodels. This deviation is relatively small, generally less than 0.5mm.

- Thickness deviation of the same mold due to different materials and blister temperatures. This deviation is relatively small, generally less than 0.1mm.

- The tolerance of thickness depends on the specific situation, and the larger the same area is pulled, the thinner the thickness of the block becomes. Different operators and temperatures can also result in varying thicknesses of the same area.

Among the above reasons, the first one is the main cause of dimensional tolerance, but since the mold can be modified and corrected, the deviation of vacuum forming can generally be controlled within 2mm.

It should be noted that the material thickness is two sizes smaller than the finished product thickness (0.05mm). Although there are phenomena where when the surface area of the finished product is much larger than that of the material, the thickness of the finished product will be much smaller than that of the material, and the surface area of the finished product will be much larger than that of the material, the overall difference is generally 0.05mm. Blister is a clearly defined “tailor-made” product, and in order to fit properly, physical samples must be taken for trial assembly.