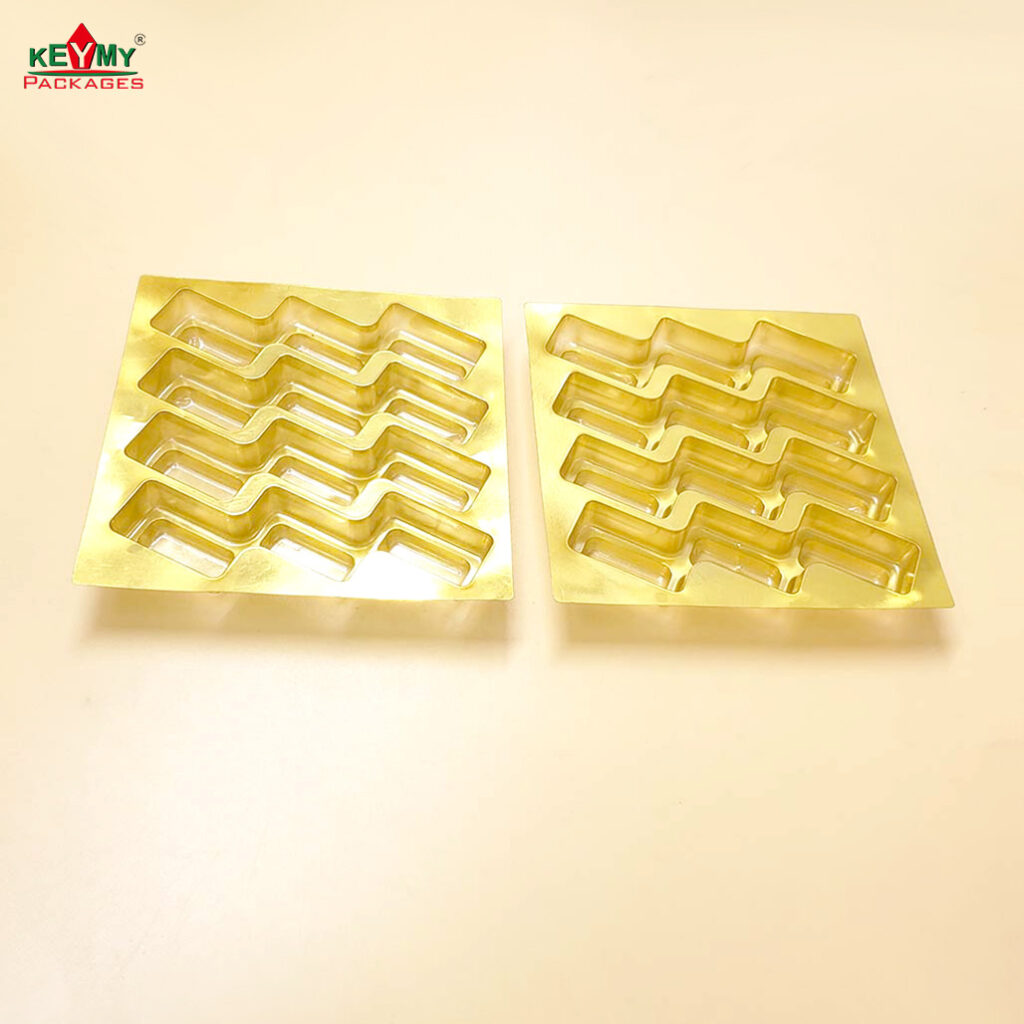

Blister inner packaging

Easy to design according to the shape of the product, which can effectively protect and display the product.

The high uniformity of vacuum molding can provide strong support and protection with thinner materials; The high precision of molding can increase the accuracy of various dimensions, making it more conducive to the fixation and handling of products.

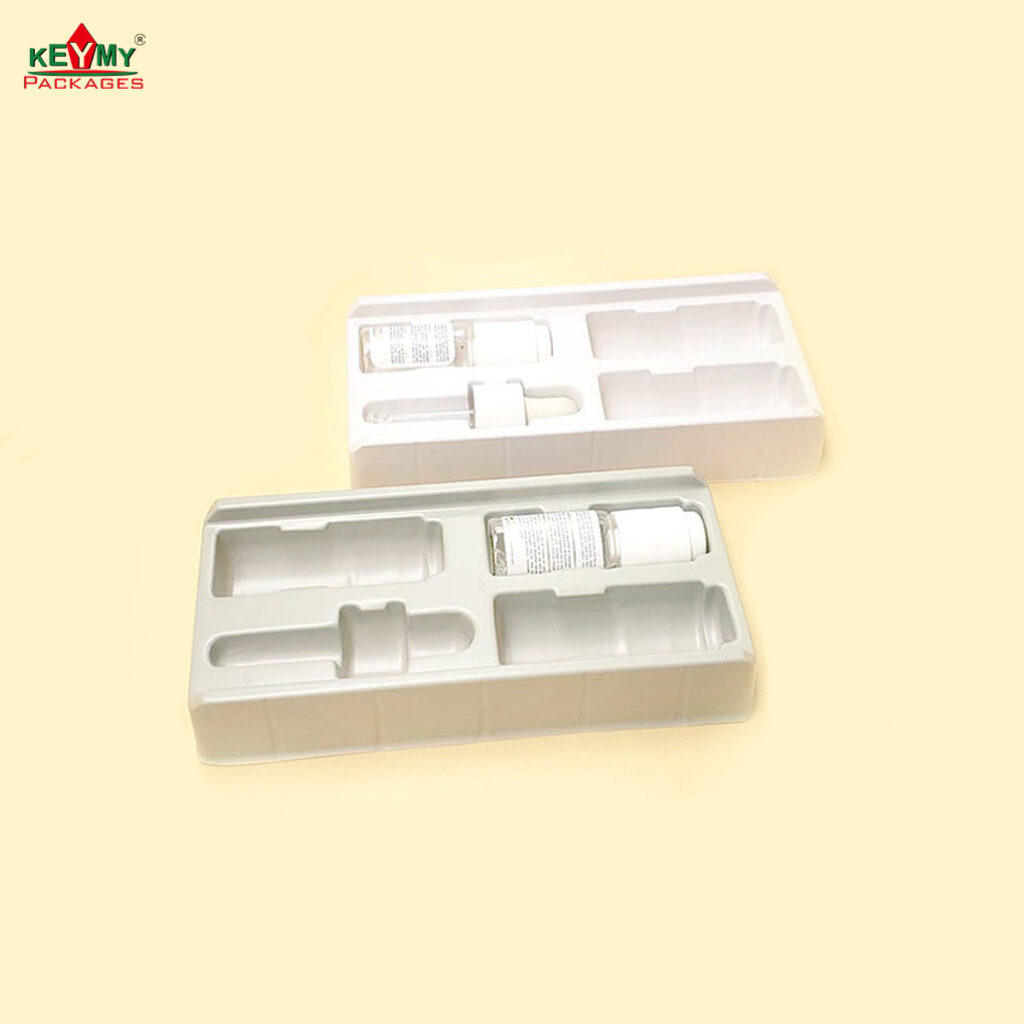

Blister packaging

As an application of outer packaging, vacuum molding is innovatively improved on the basis of vacuum molding inner packaging, which has the characteristics of short development cycle, high production efficiency, and low cost. It is an alternative solution to replace plastic boxes and paper boxes.

① Promotional packaging for fast-moving consumer goods. Based on the short development cycle and fast delivery requirements of promotional packaging for fast-moving consumer goods, a series of transparent two fold and three fold packaging methods have been developed, which have the characteristics of good display effect, short development cycle, and high production and assembly efficiency. Moreover, with innovative and unique packaging methods, there can be rich visual expressions, such as transparent, semi transparent, heel shaped, and irregular design styles that are different from traditional paper packaging, Leading a trend of fashion and environmental protection in the daily chemical market.

② Vacuum molded outer box. By exploring the vacuum forming process, we have developed techniques for cross cutting and 0 degree demolding, laying the foundation for the design of vacuum forming outer boxes and reducing the use of glue; And by replacing traditional printing methods with 3D pattern carving technology on the surface, the use of printing ink is reduced, the emissions of toxic and harmful volatile gases are reduced, and the health of workers and consumers is better protected.