Vacuum forming is a plastic processing technology, also known as vacuum forming or hot forming. It is a product formed by heating and softening plastic sheets, and then using negative pressure to adsorb them onto the mold to form the desired shape.

The vacuum forming process has the advantages of low cost, high production efficiency, and high product accuracy, and is widely used in fields such as automobiles, household appliances, medical devices, toys, etc.

The vacuum forming process mainly includes steps such as extruding plastic sheets, vacuum forming shapes, cooling, and trimming edges. The specific process is as follows:

Extrude plastic sheets

ABS, HIPS, PP, HDPE and other resin particles are dissolved and stirred at high temperatures, and finally extruded (or co extruded) to form plastic sheets required for vacuum molding

Vacuum forming shape

After the plastic board is heated and softened, it will be moved directly above the mold. Then, the plastic board will be blown from bottom to top to form a hemisphere, and the mold will be raised to make contact between the plastic board and the surface of the mold. Finally, a vacuum will be drawn between the plastic board and the mold

Cooling

The plastic shell that has just been vacuum formed needs to be cooled first, and then separated from the mold in order to maintain the same shape as the mold. In order to accelerate the cooling cycle, the use of fan equipment greatly shortens the cooling time

Trimming edges

In order to process the hole position of the product more accurately, excess material must be trimmed first. Sawing is often used during this stage, and after cutting, the edges are polished flat

Drill holes on the edge of the gong

In order to achieve a quick installation effect between vacuum molded products and other accessories, this process is necessary by drilling holes on the outer shell according to the requirements of other accessories or installation drawings.

Adhesive bonding

By using specialized adhesive, the vacuum molded plastic parts are strengthened or glued to areas that require sealing, achieving better product performance

CNC machining

In order to process the vacuum formed plastic shell more accurately and quickly, CNC is often used. CNC equipment uses computer programming to select the correct tools and angles for cutting each incision and hole position

Quality inspection

Before packaging, we carefully inspect all vacuum formed plastic shells in terms of size, surface smoothness, contour curves, color requirements, etc

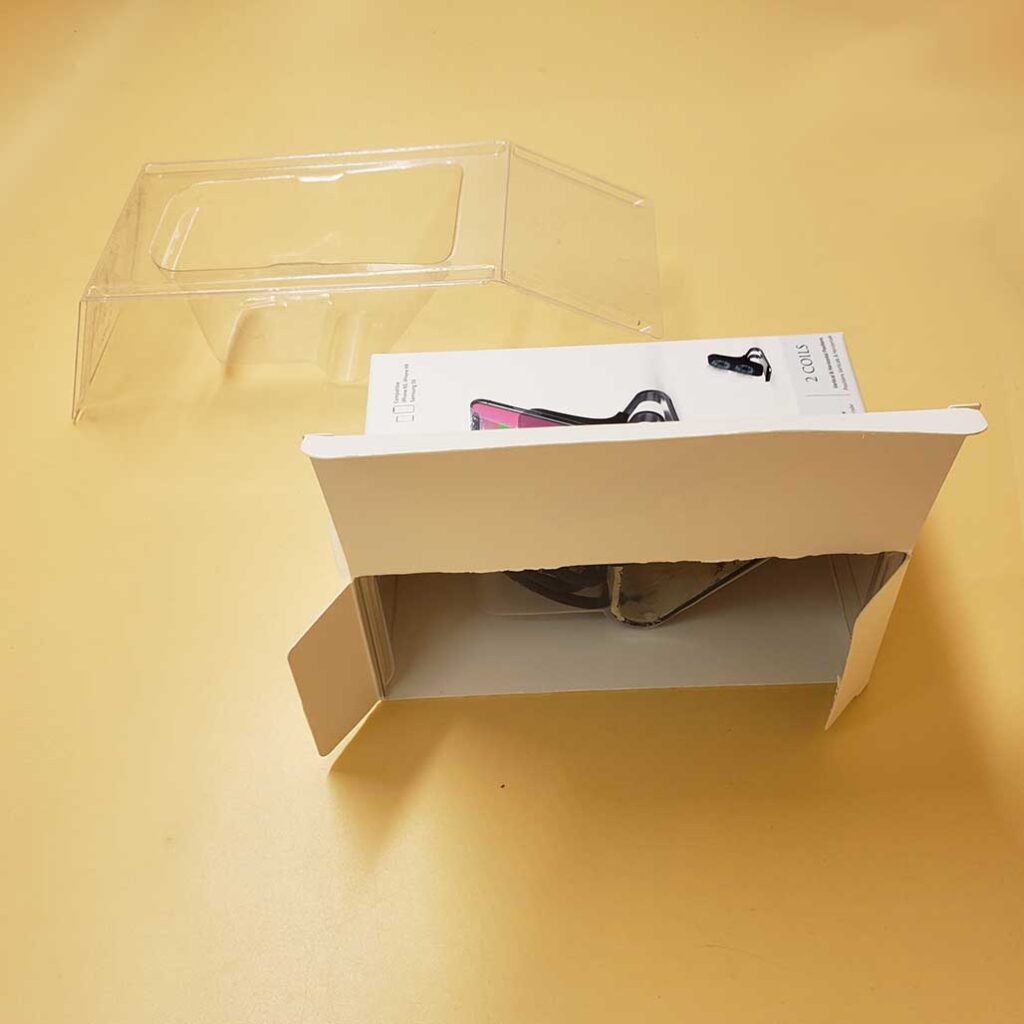

Clean packaging

All vacuum formed plastic shells are cleaned with an air gun and a specialized cloth before packaging. The product packaging is made of plastic film or cardboard boxes to prevent scratches that may affect the use of the plastic shell