Vacuum plastic packaging, also known as containerless packaging, can save a lot of packaging raw materials, reduce packaging waste, and meet the requirements of moderate and reduced packaging advocated globally.

Thick vacuum molding refers to the process where the thickness of the raw materials used exceeds 2mm and cannot be vacuum molded on a fully automatic machine. It is necessary to use a semi-automatic vacuum molding machine dedicated to thick sheet metal for processing and production. Thick vacuum molded products, due to their large area, high height, and thick material, often use the following materials for processing: acrylic (organic glass), PC, PS, ABS, PVC, etc.

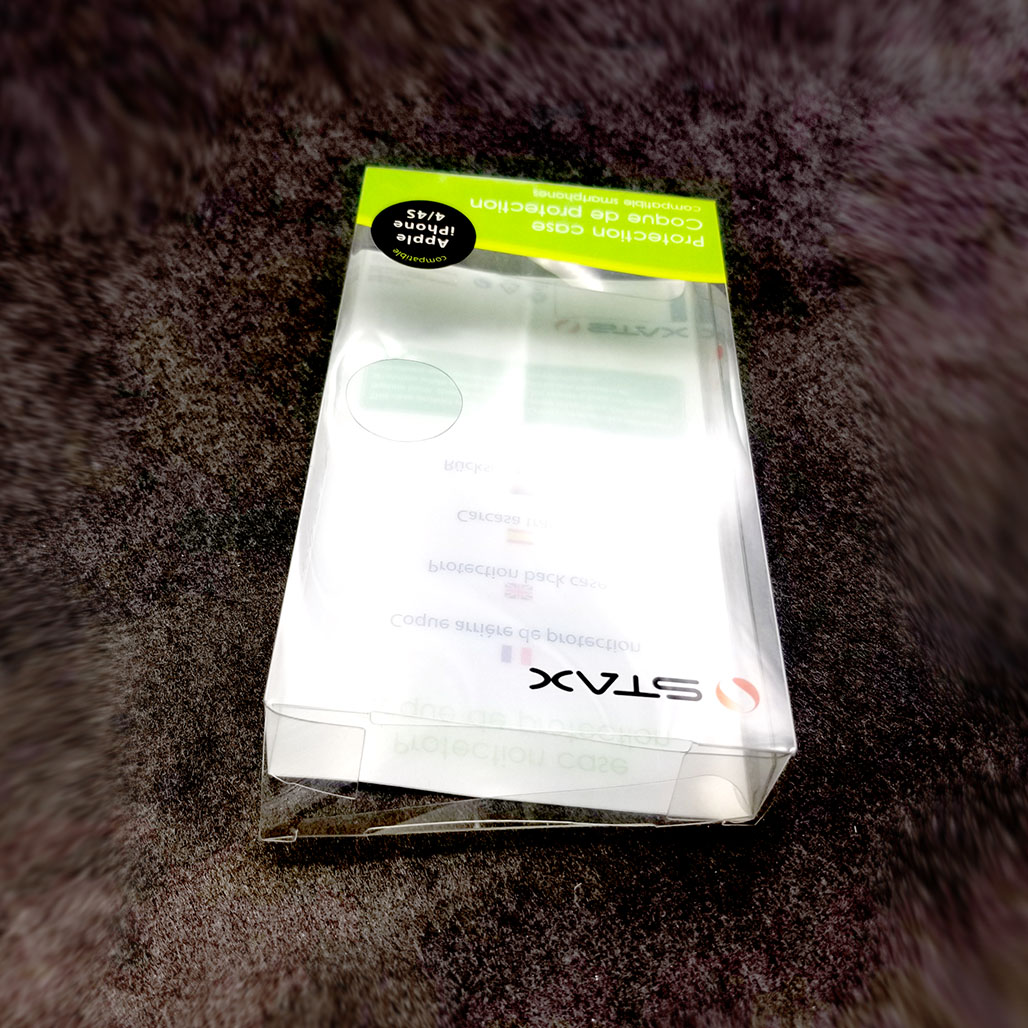

Double blister packaging refers to a packaging form that uses two blister shells to package paper cards and products together. However, its characteristic is that it requires a high-frequency machine to seal the edges of the double bubble shell, which has low efficiency and high packaging costs. However, its advantage is that the edges are neat and beautiful, and the product has a high-end appearance. The issues that need to be noted are: 1. The foam shell can only be made of PVC and PETG film, otherwise it cannot be heat sealed or the heat sealing effect is poor; The quality of the edge of the double bubble shell is determined by the quality of the high-frequency mold.

Card suction packaging refers to the process of heat sealing the bubble shell onto the surface of a paper card with vacuum oil, which is commonly seen in battery packaging in daily life. Its characteristic is to use vacuum sealing equipment to package the product between the paper card and the bubble shell.

The issues that should be noted are:

- It is required that the surface of the paper card be coated with vacuum oil (so that it can be thermally bonded with the PVC foam shell);

- The foam shell can only use PETG or PVC sheets;

- Because the bubble shell only sticks to the surface of the paper card, the packaged product is not too heavy.