Common thin film vacuum forming materials include PP, PET, PVC, PP+PP copolymer, and PE+PP copolymer.

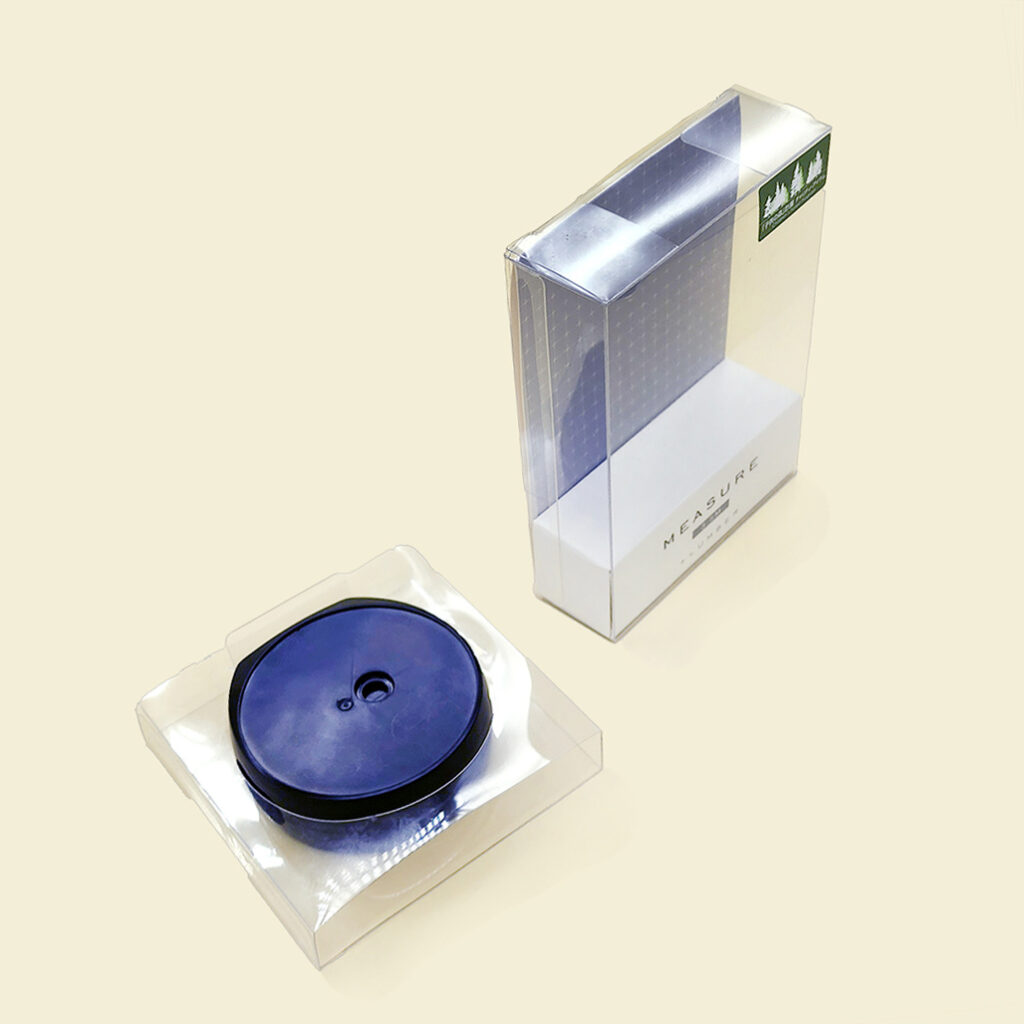

- PP material characteristics: The material is soft and tough, environmentally friendly and non-toxic, relatively resistant to high temperatures, has poor plasticity, and has difficulty in vacuum forming. The surface lacks luster, presenting a matte color.

Sensory identification: This product is white and transparent, with higher transparency compared to LDPE, and there is a sound when rubbing.

Combustion identification: During combustion, the flame is yellow on top and blue on the bottom, with a smell similar to petroleum. It melts and drips, and there is no black smoke during combustion.

- PET material characteristics: This material belongs to environmentally friendly materials, with good hardness, strong transparency, and a bright surface.

Sensory identification: This product is white and transparent, with a hard texture and a sound when rubbed. The appearance looks like PP.

Combustion identification: There is black smoke during combustion, and there is a phenomenon of flame jumping. After combustion, the surface of the material is black carbonized, and the black carbonized material is rubbed with fingers after combustion, and the carbonized material is in powder form.

- PVC material characteristics: It is one of the most commonly used materials for vacuum packaging, with moderate price, strong toughness, and good shaping ability. When encountering low temperature weather, it will become brittle and easy to break.

Sensory identification: The appearance is very similar to EVA but has elasticity.

Combustion identification: Black smoke is emitted during combustion, extinguished immediately after leaving the fire, and the combustion surface is black with no melting or dripping phenomenon.

- PP+PET material characteristics: This material belongs to composite materials, with a smooth surface, wear resistance, and good plasticity.

Sensory identification: The appearance is similar to PP, with extremely high transparency, and the sound when rubbing is greater than that of PP.

Combustion identification: There is black smoke during combustion, the flame has a jumping phenomenon, and the combustion surface appears black carbonization.

- PE+PP copolymer: It can be divided into low-density, medium density, and high-density polyethylene, with a soft feel, and is relatively less commonly used.

Sensory identification: Compared with LDPE, this product has a much higher transparency and no difference in texture. The tear test is very similar to PP film, and the material is transparent and pure white.

Combustion identification: The flame of this product is all yellow during combustion, with molten droplets, no black smoke, and a smell similar to petroleum.

PP material can be used for multiple turnover boxes. In our actual production of PP vacuum discs for customers, such as those with a thickness of 1.8 to 2.2mm, customers can use them for more than three years. However, the long-term recycling effect of other materials due to their inherent characteristics is not particularly ideal.